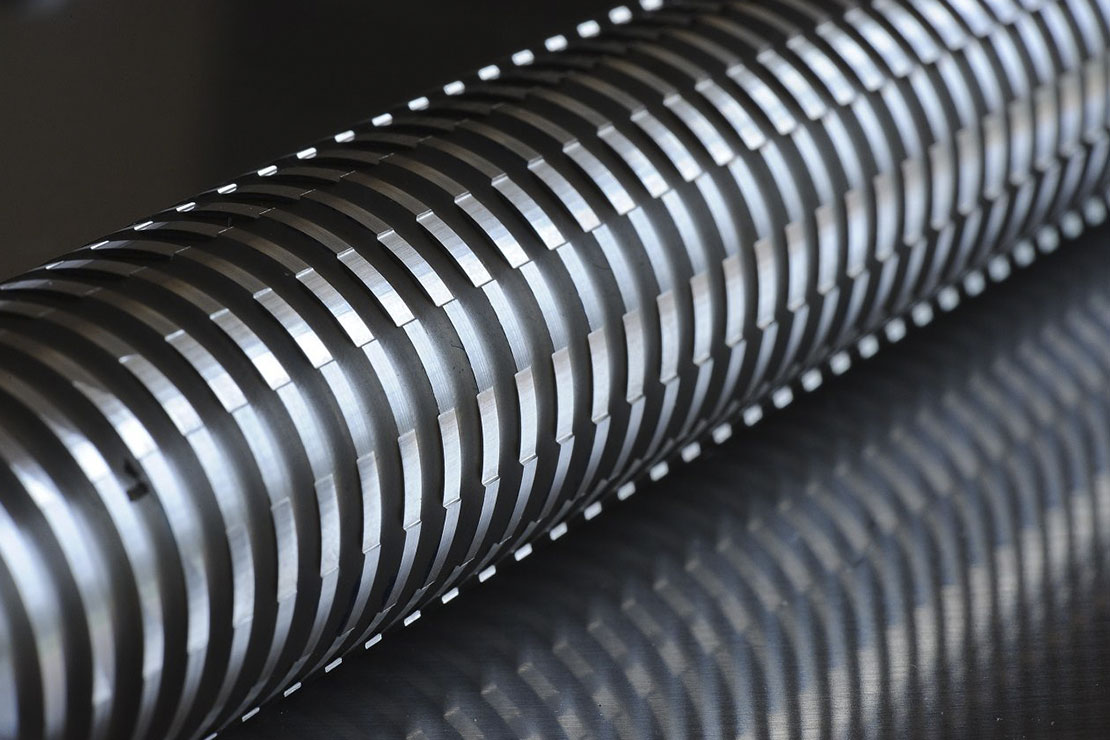

Successful production of broaching mandrels is based on experience in tool design and calculation, selection of suitable cutting material, heat treatment and precision grinding of teeth and profile. We manufacture and sharpen mandrels up to a length of approx. 800 mm (1,200 in) and can be rotary, flat or profile. We also perform sharpening of rotary and flat mandrels, regrinding or resharpening to a different profile. We grind on a CNC grinder with cooling and precise measurement of pitches and diameters.

We produce stretching and extrusion mandrels:

evolvent

for fine grooving

for pen grooves

profiling

equilateral

special

For an informative quotation, please provide us with the geometric dimensions and tolerances of the tool or workpiece, the required tool material, clamping and the expected number of pieces. We will be happy to prepare a price and time quotation for you.

On the basis of your request, we will design, offer and manufacture a suitable tool, which we will also sharpen after wear.